ABOUT US

RESEARCH

SUSTAINABILITY

Contact Us

Company Address

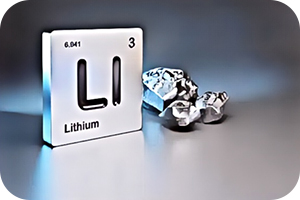

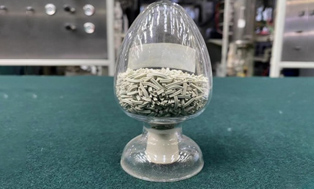

Metallic Lithium for New Energy

As a core raw material for power batteries, metallic lithium benefits from the explosive growth of electric vehicles and energy storage industries, with market demand continuously rising. By optimizing purification processes, we provide high-purity lithium products that meet the requirements of premium battery manufacturing.

Thermosensitive Dye Intermediates

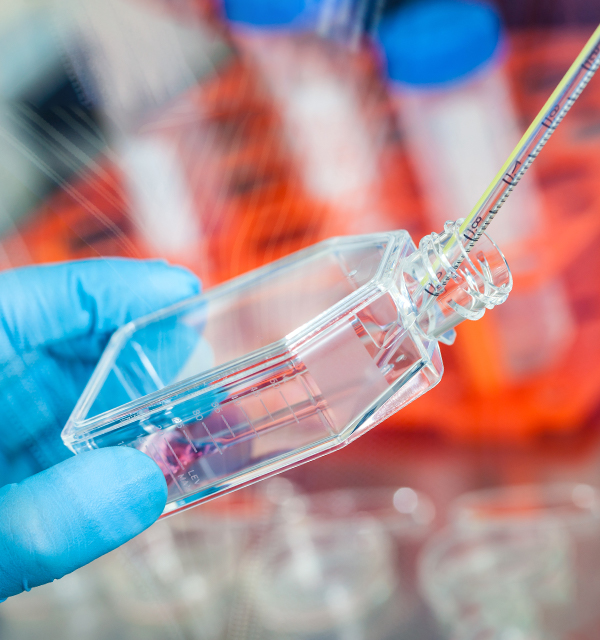

Focused on smart labels, medical testing, and ticket printing markets, our products feature high imaging sensitivity and strong stability. They are widely used in logistics traceability, medical diagnostics, and inkless printing technologies – aligning with global environmental trends.

Global Trade Division

Leveraging a globalized layout, we integrate supply chain resources to deliver customized solutions for downstream clients across Asia, Europe, and North America. Through strict quality control, flexible supply chains, and localized services, we continuously enhance competitiveness in new energy materials and specialty chemicals, striving to become a core global supplier.

Dye Intermediate

We have been deeply engaging in the ??thermal dye field?? for many years, providing key intermediates for thermal dye developers, such as ??DPA (Diphenylamine) and BBA (Benzyl Benzoate)??. To better serve our customers, we have also continuously upgraded our ??developers and sensitizers??, introducing more ??eco-friendly solutions??.

Pharmaceuticals

"In specialized segments, the chemical pharmaceutical sector is poised for accelerated consolidation amid industrial upgrading and competitive transformation, with projections indicating a return to positive growth by 2025. Our brominated alkane products have gained deep recognition among select pharmaceutical industry clients. In 2025, our lithium metal products will continue delivering value to our pharmaceutical sector customers."?

Catalyst

??Brominated alkanes exhibit diverse properties and applications.?? For example, many bromides such as ??bromopropane?? and ??bromobutane?? are widely used in the ??chemical, pharmaceutical, and materials industries.?? They can serve as ??catalysts, stabilizers??, and raw materials for specific products. Additionally, certain bromides are utilized in the production of ??flame retardants and fire extinguishing agents?? to mitigate fire hazards

New energy

?"Lithium metal (Li)??, a silvery-white soft metal, is the lightest naturally occurring metallic element. It is widely used in ??atomic energy, aerospace, alloy materials, lithium batteries, controlled nuclear fusion reactors, synthetic rubber, and pharmaceutical industries??, and is considered the preferred anode material for next-generation high-energy lithium secondary batteries. "Industrial-grade lithium metal (purity ≥96.5%) exhibits broad catalytic utility. In pharmaceuticals, it facilitates synthesis of oncology therapeutics (e.g., kinase inhibitors), antiretrovirals (e.g., HIV protease inhibitors), and cardiovascular agents (e.g., statins). Petrochemical applications focus on generating organolithium reagents (e.g., n-BuLi) for C-C bond formation, while fine chemical uses include Ziegler-Natta polymerization catalysts and terpenoid flavor synthesis." Lithium metal is a core material in the new energy sector, primarily used for manufacturing lithium battery anodes (particularly lithium metal batteries) and next-generation solid-state batteries. It significantly enhances battery energy density and extends the driving range of electric vehicles. As a lightweight, high-energy carrier, it serves as a critical foundational material for advancing high-performance power batteries and energy storage technologies.

We have been deeply engaging in the ??thermal dye field?? for many years, providing key intermediates for thermal dye developers, such as ??DPA (Diphenylamine) and BBA (Benzyl Benzoate)??. To better serve our customers, we have also continuously upgraded our ??developers and sensitizers??, introducing more ??eco-friendly solutions??.

"Primarily used in the thermal paper field, what is thermal paper? Thermal paper is a coated paper manufactured by applying a 'thermal coating' (also called a thermosensitive layer) onto high-quality base paper. When the paper passes through a thermal print head, the chemicals in the coating react to heat, producing corresponding text or graphics. The thermal coating mainly consists of three chemicals: dye, developer, and sensitizer. These three components are ground in a sand mill at specific ratios, mixed with dispersed calcined kaolin, and combined with binders and additives before being coated onto paper using a coating machine to produce thermal paper.??

??Applications of thermal paper? In commercial activities, it is used for labels, POS receipts, etc. In medical and measurement systems, it serves as recording material, such as ECG paper and industrial instrument logs. In fax machines, it acts as a communication medium for text and graphics (i.e., fax paper) and is applied in internet terminal printing, among other uses."?

"In specialized segments, the chemical pharmaceutical sector is poised for accelerated consolidation amid industrial upgrading and competitive transformation, with projections indicating a return to positive growth by 2025. Our brominated alkane products have gained deep recognition among select pharmaceutical industry clients. In 2025, our lithium metal products will continue delivering value to our pharmaceutical sector customers."?

??Brominated alkanes exhibit diverse properties and applications.?? For example, many bromides such as ??bromopropane?? and ??bromobutane?? are widely used in the ??chemical, pharmaceutical, and materials industries.?? They can serve as ??catalysts, stabilizers??, and raw materials for specific products. Additionally, certain bromides are utilized in the production of ??flame retardants and fire extinguishing agents?? to mitigate fire hazards

?"Lithium metal (Li)??, a silvery-white soft metal, is the lightest naturally occurring metallic element. It is widely used in ??atomic energy, aerospace, alloy materials, lithium batteries, controlled nuclear fusion reactors, synthetic rubber, and pharmaceutical industries??, and is considered the preferred anode material for next-generation high-energy lithium secondary batteries.

"Industrial-grade lithium metal (purity ≥96.5%) exhibits broad catalytic utility. In pharmaceuticals, it facilitates synthesis of oncology therapeutics (e.g., kinase inhibitors), antiretrovirals (e.g., HIV protease inhibitors), and cardiovascular agents (e.g., statins). Petrochemical applications focus on generating organolithium reagents (e.g., n-BuLi) for C-C bond formation, while fine chemical uses include Ziegler-Natta polymerization catalysts and terpenoid flavor synthesis."

Lithium metal is a core material in the new energy sector, primarily used for manufacturing lithium battery anodes (particularly lithium metal batteries) and next-generation solid-state batteries. It significantly enhances battery energy density and extends the driving range of electric vehicles. As a lightweight, high-energy carrier, it serves as a critical foundational material for advancing high-performance power batteries and energy storage technologies.

Leveraging a profound academic heritage and years of industry expertise, our professional technical team consistently adheres to rigorous and practical service standards. We provide scientifically grounded professional advice and comprehensive technical guidance throughout the entire process, tailored to the physicochemical properties, application scenarios, and usage specifications of various chemical products.

Through comprehensive analysis of clients' actual production conditions, process flows, and cost-control factors, we develop customized solutions for diverse requirement scenarios:

For new product evaluation: We offer small-batch sampling services and multi-dimensional performance testing plans.

For scaled production needs: We design scientific procurement cycles and quality control systems to ensure raw material supply stability and production continuity.

Through systematic technical verification and continuous optimization mechanisms, we will formulate targeted implementation plans that balance technical feasibility with cost-effectiveness. This empowers clients to achieve enhanced chemical production efficiency and meet sustainable development goals.

Industrial grade: Primary purity ≥99% Battery grade: Primary purity ≥99.9% Featuring high catalytic activity, superior surface quality, uniform particle distribution, and virtually residue-free composition.

Bromides such as N-propyl bromide and N-butyl bromide are widely used in chemical, pharmaceutical, and material industries, among others. They serve as catalysts, stabilizers, and raw materials for specialized materials.

Thermal microcapsules not only optimize the coating structure but also enhance the performance of thermal paper, meeting the demands for high-quality thermal paper across diverse application scenarios.